A guide to our alternative lead roof flashings

A Guide to Lead Alternative Roof Flashings

Brits love a moan about the rain and, at Burton Roofing Merchants we talk a lot about your roof being a barrier to the weather. In terms of roofing, the most pervasive and difficult element of our weather control is water and a Lead or Lead alternative roof flashings are an important componant on most roofs.

The flashing is usually the last line of defence in the battle against water penetration and is required at any point where two roofing surfaces meet: including valleys, around chimneys, roof penetrations (e.g. windows), eaves, rakes, ridges and at roof-to-wall intersections.

Perhaps the most time-consuming aspect of a roofer’s work and most important to get right, a roof flashing product must be durable, low maintenance, weather resistant, flexible and compatible with adjacent materials. Traditionally Lead has met all these requirements and for the ultimate in good appearance and in heritage settings, Lead is unsurpassed. When laid correctly, depending on the code used, Lead has been proven to last up to 150+ years, but installation does require an experienced craftsperson, can be time consuming and, depending on the location of use, could require ongoing maintenance.

The benefits of alternative Lead roof flashings

Alternatives to Lead flashing can be used for roofing, pipe work and other similar applications in these locations. They have a number of benefits over lead flashing:

- As an anti-theft alternative - High value, and the fact it’s so easily recyclable, means Lead theft is a real problem. Uninhabited buildings with Lead roofs or gutters and pipework made from Lead are an easy target. The theft of Lead flashing and Lead slate not only cause the need for expensive replacement, but also often results in higher insurance costs for the owners.

- For affordability - Having a lower initial cost and no second hand or scrap value, some deliberately don’t even look like traditional Lead to ensure theft and vandalism are eliminated. The perfect Insurance solution!

- For speed and ease of installation - With similar flexibility and malleability to Lead, lead flashing alternatives are suitable for domestic properties too. They can be stretched without using forming tools, making complex detailing and shaping around profiled tiles and standing seams straightforward. Some non-Lead flashing alternatives have a self-adhesive backing. In most cases they can be cut with knives or snips making your job easier.

What are the ‘best’ lead alternative flashings?

We have a range BBA Certified Lead alternatives from leading manufacturers, all of which are innovatively manufactured slightly differently to suit specific needs and preferences. Whether you need certain colour, texture, thickness and malleability, you’ll find the Lead replacement flashing type that works best for you in our following options:

Alcan

What is is? A rust- resistant aluminium metal flashing with a highly reflective finish. It has excellent weld and workability meaning it is ideal for roofing applications.

Suitability: Alcan is a popular choice with DIYers for roof flashing installation due to its flexibility and ease of working. Aluminium is a mid-ranged metal flashing material that holds its shape well. With a thickness of 0.6mm is easier to bend and manipulate than steel.

Please note: Uncoated aluminium should not be placed in direct contact with concrete, mortar, fibre-cement tiles. The alkalinity in the cement corrodes the aluminium.

What are they? Produced from sheet aluminium with a protective polyurethane coating on top and a polyisobutylene adhesive on the underside, Alto Lead and Alto Lead Plus are self-adhesive Lead-free alternatives.

Suitability:Both flat roofing and pitched roofing applications.

Alto Lead was developed as a cost-effective solution to the problems associated with Lead theft. It has a dimpled profile.

Alto Lead Plus was developed to provide more lead-like properties. Smooth in appearance, it’s constructed from 3 layers of modified plastics. The integrated expanded aluminium mesh has a full backing of polyisobutylene with an easy to remove two-part silicone film release paper.

The polyisobutylene adhesive ensures a strong permanent bond to all building materials. Without a primer (unless your surface is extremely unstable) it forms a watertight joint that requires no additional tape or sealant.

Guarantee: Both Alto Lead and Alto Lead Plus offer a product guarantee of 15 years with a life expectancy in excess of 20 years.

Wakaflex

Wakaflex ® is made from aluminium honeycomb mesh embedded into UV resistant butyl rubber. It has a high strength, self-adhesive Butylon® backing and a smooth face which repels dirt. The lightweight material is laid in long lengths and is easy to apply due to high ‘stretchability’ - up to 50% lengthwise & 15% crosswise of the material. It has a unique product composition and a self-welding effect. Unlike lead, it is not susceptible to cold working fatigue and is resistant to thermal movement.

Suitability: All wall abutments, chimneys and other rising parts of structures such as dormers. sealing gas, oil and wood burner flue penetrations, plain tiled and other double-lapped roofs. Non-toxic, it is environmentally safe and can therefore be used with rainwater harvesting systems. Also suitable for use close-proximity to Green Roofs.

Please note: Wakaflex ® is not compatible with bituminous material. It must not be installed in a way that allows ponding can occur.

Guarantee: 10 years against manufacturing defect.

https://www.youtube.com/watch?v=OM_bCI2-g6I

Ubiflex

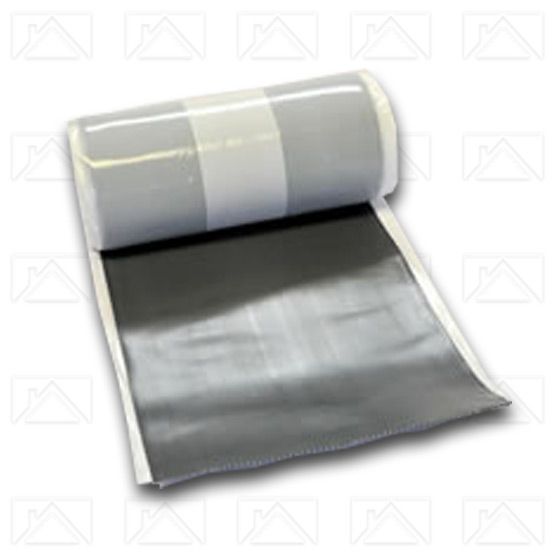

Ubiflex B3 is a non-lead waterproof flashing material manufactured from reinforced aluminium mesh with a mixture of modified bitumen. It has a black, granular finish, and is BRE tested.

Suitability: Ubiflex B3 (3.5mm in thickness) Ubiflex can be used in most applications where lead is traditionally used, to provide a weatherproof junction at features such as a change of direction and materials. It is suitable for direct contact with any building material, including copper, zinc, iron, aluminium and stainless steel, in most climate conditions and environments.

Please note It is not suitable for sharp corners.

Guarantee: Product guarantee of 25 years

Ubiflex Extreme (2.5mm in thickness) is manufactured by coating both sides of reinforced aluminium mesh with silicone sheeting. It has a smooth finish and looks similar to lead, making it ideal for applications where aesthetics are important. One side is grey, the other is black. Install either side up to suit your requirements. It has the same product benefits and installation features as Ubbiflex B3. But is so called because it was created to withstand harsh weather conditions including a temperature range between -30°C and +180°C.

It has been tested at the BRE for both wind and fire, withstanding up to 100mph winds and passing with a Class A fire rating. 30 years tested to methods of artificial ageing by long term exposure to UV (A&B) radiation, elevated temperature and water. Individually and in combinations of two and all three elements.

For more information on lead alternative roof flashings please see the relevant product page, get in touch with us or use the live chat function on the website now.